The foundation of any building is arguably its most critical element. Without a stable, well-constructed foundation, even the most beautifully designed structures risk failure. Among the different types of foundations used in construction, the strip foundation is one of the most common and reliable. It offers an excellent balance of cost, simplicity, and durability, making it a popular choice for residential and small-scale commercial buildings.

If you are based in London and searching for a strip foundation, this comprehensive guide will walk you through everything you need to know from what it is, how it is constructed, it’s benefits, and why Concrete King is your ultimate partner for building a strip foundation.

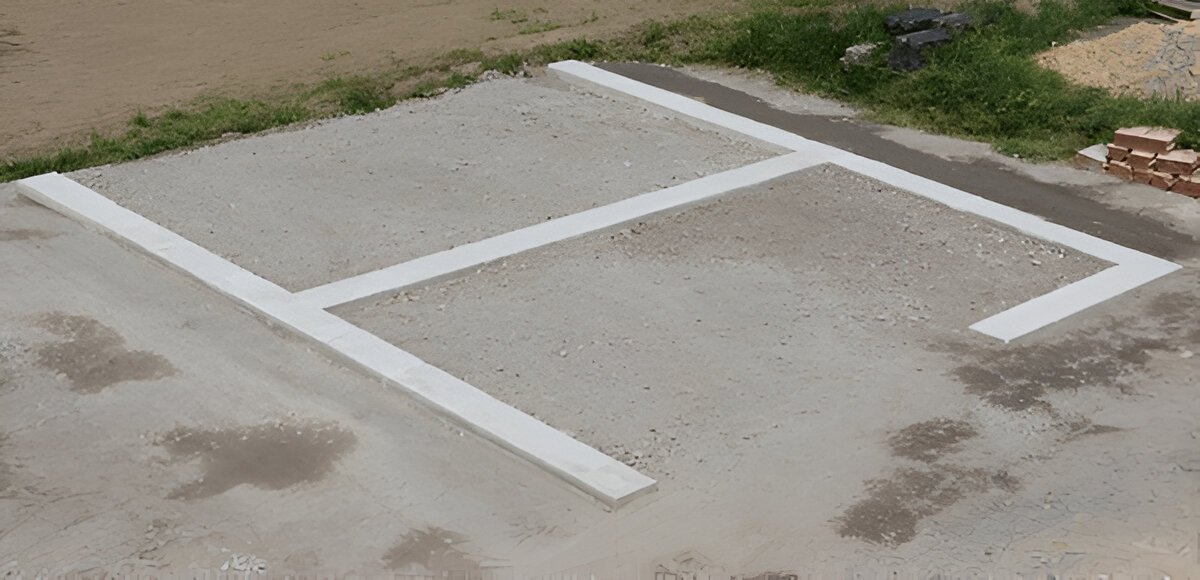

A strip foundation is a type of shallow foundation where a continuous strip of concrete is poured to support load-bearing walls. The weight of the building is evenly distributed across the strip, which sits on firm soil. This type of foundation is widely used in both residential and commercial construction due to its efficiency and affordability.

Key Characteristics of a Strip Foundation

A strip foundation is the preferred choice in the following scenarios:

Strip foundations can be tailored to suit different building needs and ground conditions. Here are the most common types:

Usage: Best for lightweight buildings.

Features: Made entirely of concrete without reinforcement.

Pros: Simple and cost-effective.

Usage: Ideal for heavier structures or buildings on uneven ground.

Features: Includes steel reinforcement bars to add strength.

Pros: More durable and resistant to cracking.

Usage: Suitable for buildings with wide walls or heavy loads.

Features: Wider strips of concrete distribute weight more effectively.

Pros: Provides additional stability.

The construction of a strip foundation involves several precise steps. Proper execution at each stage ensures the foundation’s integrity and longevity.

Step 1: Site Survey and Soil Investigation

Before any construction begins, a site survey and soil test are performed to assess ground conditions and determine the appropriate depth and width of the foundation.

Step 2: Excavation of Trenches

Once the foundation dimensions are finalized, trenches are dug. The depth depends on the building’s weight and soil strength, typically ranging from 450mm to 900mm.

Step 3: Laying the Concrete

Concrete is poured into the trenches, creating a continuous strip. For reinforced foundations, steel bars are placed within the trench before pouring.

Step 4: Curing the Concrete

Curing allows the concrete to achieve its full strength. The curing process usually takes 7-28 days, depending on weather conditions and project requirements.

Step 5: Building the Superstructure

Once the foundation is ready, construction of the walls and other structural elements begins.

1. Cost-Efficiency

Strip foundations require less excavation and concrete than deep foundations, making them more affordable without compromising quality.

2. Time-Saving

Their simplicity ensures faster construction compared to other foundation types, keeping your project on schedule.

3. Strength and Durability

A properly constructed strip foundation provides a long-lasting base, even in challenging environments.

4. Eco-Friendly

By minimizing excavation and material use, strip foundations have a lower environmental impact.

Even though strip foundations are straightforward, challenges can arise. Here’s how to address them:

1. Weak Soil Conditions

Problem: Soil near the surface lacks the strength to support the structure.

Solution: Opt for a reinforced or wide strip foundation, or consider deeper excavation.

2. Waterlogging

Problem: Groundwater or rainwater can weaken the foundation.

Solution: Implement proper drainage systems around the foundation.

3. Cracking in Concrete

Problem: Poor-quality concrete or inadequate curing can cause cracks.

Solution: Use high-grade concrete and follow proper curing procedures.

4. Unstable Surroundings

Problem: Nearby construction or natural shifts in soil can destabilize the foundation.

Solution: Conduct regular inspections and consider additional reinforcement if needed.

North London’s soil types and typical building structures make strip foundations a practical choice. The compact, stable ground in most areas allows for shallow excavation, while the affordability of strip foundations aligns with budget-conscious projects.

The quality of materials directly impacts the performance of a strip foundation. Key considerations include:

Concrete Grade: Use high-grade concrete (e.g., C25 or higher) for maximum strength and durability.

Reinforcement Bars: For reinforced foundations, select corrosion-resistant steel.

Aggregates: Ensure aggregates are clean and appropriately graded for consistent concrete quality.

At Concrete King, we specialize in providing premium concrete solutions tailored to your construction needs. Here is why North London builders trust us:

1. High-Quality Concrete

Our concrete is manufactured to industry standards, ensuring your strip foundation is durable and reliable.

2. Expert Advice

Not sure what type of strip foundation you need? Our experts guide you through the entire process, from soil testing to material selection.

3. Timely Delivery

We understand the importance of meeting deadlines. Our team ensures your materials are delivered promptly to keep your project on track.

4. Affordable Pricing

With competitive rates, we make premium concrete accessible without breaking the bank.

5. Sustainability Commitment

We prioritize eco-friendly practices, ensuring minimal environmental impact during the manufacturing process.

A strip foundation is more than just a base, it’s the backbone of your building. With the right materials and construction techniques, it ensures stability, safety, and longevity. When you choose Concrete King, you are not just buying concrete, you are investing in quality, expertise, and peace of mind.

Ready to start your project in North London? Trust the professionals at Concrete King to deliver top-quality concrete and expert guidance.

Visit our website to learn more about how we can support your strip foundation project!

Whether it’s the amount of ready mixed concrete to be used for concrete slabs, or working out how much needs to be combined with coarse aggregate, we’ve got the solution.

To place your order or to discuss your requirements further please contact our friendly team today who will be happy to help with the concrete mix calculator.

Visit our Concrete Calculator page where you can access more calculate options.